|

|

| GROOVED

FITTINGS |

|

|

|

|

|

Rigid

Grooved Coupling (silver) |

Rigid

Grooved Coupling |

Rigid

Grooved reducer Coupling |

Grooved

Coupling- Concentric Reducer |

Grooved

Coupling-Threaded Concentric Reducer |

|

|

|

|

|

Grooved

Coupling-Threaded Reducing Tee |

Grooved

Coupling-Reducing Cross |

Grooved

Coupling-Reducing Tee |

Grooved

Coupling-Cross |

Grooved

Coupling-Threaded Reducing Cross |

|

|

|

|

|

Grooved

Coupling-Mechanical Cross |

Grooved

Coupling-Mechanical Tee |

Grooved

Coupling-End Cap |

Grooved

Coupling-Threaded Mechanical Cross |

Grooved

Coupling-Threaded Mechanical Tee |

|

|

|

|

|

Grooved

Coupling-45° Elbow |

Grooved

Coupling-Elbow |

Grooved

Coupling-Tee |

Grooved

Coupling-Adaptor Flange |

PN

1.6MPa Grooved Split Flange |

|

|

|

|

|

|

|

|

|

|

| |

Materials:QT450-10

ASTM A234 WCB

Specifications:DN60-530

Standards:GB 5135.11-2006

Working Pressure:1.2MPa,1.6MPa,2.5MPa,4.0MPa,8.0MPa |

|

| |

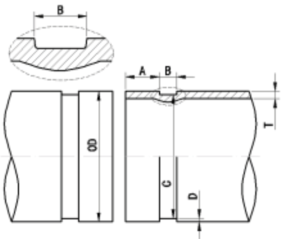

沟槽参数 |

|

| |

|

|

|

规格 |

密封面 |

沟槽宽 |

槽底直径C |

沟槽深 |

最小壁厚 |

管端张口 |

|

公称直径 |

实际外径OD |

公差 |

A |

B |

标准 |

公差 |

D(参考) |

T |

F |

| |

|

|

|

|

|

|

|

|

|

|

|

20 |

26.7 |

+0.25 |

-0.25 |

15.88 |

7.14 |

23.83 |

-0.38 |

1.42 |

1.65 |

29.2 |

| 3/4 |

1.050 |

+0.010 |

-0.010 |

0.625 |

0.281 |

0.938 |

-0.015 |

0.056 |

0.065 |

1.15 |

|

25 |

33.4 |

+0.33 |

-0.68 |

15.88 |

7.14 |

30.23 |

-0.38 |

1.6 |

1.65 |

34.5 |

|

1 |

1.315 |

+0.013 |

-0.027 |

0.625 |

0.281 |

1.190 |

-0.015 |

0.063 |

0.065 |

1.36 |

|

32 |

42.4 |

+0.41 |

-0.60 |

15.88 |

7.14 |

38.99 |

-0.38 |

1.6 |

1.65 |

45.0 |

|

1 1/4 |

1.660 |

+0.016 |

-0.024 |

0.625 |

0.281 |

1.535 |

-0.015 |

0.063 |

0.065 |

1.77 |

|

40 |

48.3 |

+0.48 |

-0.52 |

15.88 |

7.14 |

45.09 |

-0.38 |

1.6 |

1.65 |

51.1 |

|

1 1/2 |

1.900 |

+0.019 |

-0.020 |

0.625 |

0.281 |

1.775 |

-0.015 |

0.063 |

0.065 |

2.01 |

|

50 |

57.0 |

+0.61 |

-0.61 |

15.88 |

8.74 |

53.85 |

-0.38 |

1.6 |

1.65 |

59.7 |

|

2 1/4 OD |

2.250 |

+0.024 |

-0.024 |

0.625 |

0.344 |

2.120 |

-0.015 |

0.063 |

0.065 |

2.35 |

|

50 |

60.3 |

+0.61 |

-0.61 |

15.88 |

8.74 |

57.15 |

-0.38 |

1.6 |

1.65 |

63.0 |

|

2 |

2.375 |

+0.024 |

-0.024 |

0.625 |

0.344 |

2.250 |

-0.015 |

0.063 |

0.065 |

2.48 |

|

65 |

73.0 |

+0.74 |

-0.74 |

15.88 |

8.74 |

69.09 |

-0.46 |

1.98 |

2.11 |

75.7 |

|

2 1/2 |

2.875 |

+0.029 |

-0.029 |

0.625 |

0.344 |

2.720 |

-0.018 |

0.078 |

0.083 |

2.98 |

|

65 |

76.1 |

+0.76 |

-0.76 |

15.88 |

8.74 |

72.26 |

-0.46 |

1.98 |

2.11 |

78.7 |

|

3 OD |

3.000 |

+0.030 |

-0.030 |

0.625 |

0.344 |

2.845 |

-0.018 |

0.078 |

0.083 |

3.10 |

|

80 |

88.9 |

+0.89 |

-0.79 |

15.88 |

8.74 |

84.94 |

-0.46 |

1.98 |

2.11 |

91.4 |

|

3 |

3.500 |

+0.035 |

-0.031 |

0.625 |

0.344 |

3.344 |

-0.018 |

0.078 |

0.083 |

3.60 |

|

90 |

101.6 |

+1.02 |

-0.79 |

15.88 |

8.74 |

97.38 |

-0.51 |

2.11 |

2.11 |

104.1 |

|

3 1/2 |

4.000 |

+0.040 |

-0.031 |

0.625 |

0.344 |

3.834 |

-0.020 |

0.083 |

0.083 |

4.10 |

|

100 |

108.0 |

+1.09 |

-0.79 |

15.88 |

8.74 |

103.73 |

-0.51 |

2.11 |

2.11 |

110.5 |

|

4 1/4 OD |

4.262 |

+0.043 |

-0.031 |

0.625 |

0.344 |

4.084 |

-0.020 |

0.083 |

0.083 |

4.35 |

|

100 |

114.3 |

+1.14 |

-0.79 |

15.88 |

8.74 |

110.08 |

-0.51 |

2.11 |

2.11 |

116.8 |

|

4 |

4.500 |

+0.045 |

-0.031 |

0.625 |

0.344 |

4.334 |

-0.020 |

0.083 |

0.083 |

4.60 |

|

120 |

127.0 |

+1.27 |

-0.79 |

15.88 |

8.74 |

122.78 |

-0.51 |

2.11 |

2.41 |

129.5 |

|

4 1/2 |

5.000 |

+0.050 |

-0.031 |

0.625 |

0.344 |

4.834 |

-0.020 |

0.083 |

0.095 |

5.10 |

|

125 |

133.0 |

+1.35 |

-0.79 |

15.88 |

8.74 |

129.13 |

-0.51 |

2.11 |

2.77 |

135.9 |

|

5 1/4 OD |

5.250 |

+0.053 |

-0.031 |

0.625 |

0.344 |

5.084 |

-0.020 |

0.083 |

0.109 |

5.35 |

|

125 |

139.7 |

+1.42 |

-0.79 |

15.88 |

8.74 |

135.48 |

-0.51 |

2.11 |

2.77 |

142.2 |

|

5 1/2 OD |

5.500 |

+0.056 |

-0.031 |

0.625 |

0.344 |

5.334 |

-0.020 |

0.083 |

0.109 |

5.60 |

|

125 |

141.3 |

+1.42 |

-0.79 |

15.88 |

8.74 |

137.03 |

-0.51 |

2.11 |

2.77 |

143.8 |

|

5 |

5.563 |

+0.056 |

-0.031 |

0.625 |

0.344 |

5.395 |

-0.020 |

0.083 |

0.109 |

5.66 |

|

150 |

159.0 |

+1.60 |

-0.79 |

15.88 |

8.74 |

154.68 |

-0.56 |

2.16 |

2.77 |

161.3 |

|

6 1/4 OD |

6.260 |

+0.063 |

-0.031 |

0.625 |

0.344 |

6.090 |

-0.022 |

0.085 |

0.109 |

6.35 |

|

150 |

165.1 |

+1.60 |

-0.79 |

15.88 |

8.74 |

160.78 |

-0.56 |

2.16 |

2.77 |

167.6 |

|

6 1/2 OD |

6.500 |

+0.063 |

-0.031 |

0.625 |

0.344 |

6.330 |

-0.022 |

0.085 |

0.109 |

6.60 |

|

150 |

168.3 |

+1.60 |

-0.79 |

15.88 |

8.74 |

163.96 |

-0.56 |

2.16 |

2.77 |

170.9 |

|

6 |

6.626 |

+0.063 |

-0.031 |

0.625 |

0.344 |

6.455 |

-0.022 |

0.085 |

0.109 |

6.73 |

|

200 |

203.2 |

+1.60 |

-0.79 |

19.05 |

11.91 |

198.53 |

-0.64 |

2.34 |

2.77 |

207.5 |

|

8 |

8.000 |

+0.063 |

-0.031 |

0.750 |

0.469 |

7.816 |

-0.025 |

0.092 |

0.109 |

8.17 |

|

200A |

216.3 |

+1.60 |

-0.79 |

19.05 |

11.91 |

211.61 |

-0.64 |

2.34 |

2.77 |

220.7 |

|

8 |

8.500 |

+0.063 |

-0.031 |

0.750 |

0.469 |

8.331 |

-0.025 |

0.092 |

0.109 |

8.69 |

|

200 |

219.1 |

+1.60 |

-0.79 |

19.05 |

11.91 |

214.40 |

-0.64 |

2.34 |

2.77 |

223.5 |

|

8 |

8.626 |

+0.063 |

-0.031 |

0.750 |

0.469 |

8.441 |

-0.025 |

0.092 |

0.109 |

8.80 |

|

250A |

267.4 |

+1.60 |

-0.79 |

19.05 |

11.91 |

262.6 |

-0.69 |

2.39 |

3.40 |

271.8 |

|

10 |

10.500 |

+0.063 |

-0.031 |

0.750 |

0.469 |

10.339 |

-0.027 |

0.094 |

0.134 |

10.70 |

|

250 |

273.0 |

+1.60 |

-0.79 |

19.05 |

11.91 |

268.28 |

-0.69 |

2.39 |

3.40 |

277.4 |

|

10 |

10.750 |

+0.063 |

-0.031 |

0.750 |

0.469 |

10.562 |

-0.027 |

0.094 |

0.134 |

10.92 |

|

300 |

318.4 |

+1.60 |

-0.79 |

19.05 |

11.91 |

312.90 |

-0.69 |

2.77 |

3.96 |

322.8 |

|

12 |

12.500 |

+0.063 |

-0.031 |

0.750 |

0.469 |

12.319 |

-0.027 |

0.109 |

0.156 |

12.71 |

|

300 |

323.9 |

+1.60 |

-0.79 |

19.05 |

11.91 |

318.29 |

-0.69 |

2.77 |

3.96 |

328.2 |

|

12 |

12.750 |

+0.063 |

-0.031 |

0.750 |

0.469 |

12.531 |

-0.027 |

0.109 |

0.156 |

12.92 |

|

沟槽参数: |

|

|

|

|

|

|

|

|

|

|

1,允许的管道椭圆度不应超过1%。 |

|

2,最大与最小的管道直径之间过大的差距将导致接头安装的困难。 |

|

3,管端的垂直度允许的最大公差:DN15-90(1/2~3-1/2)为0.76mm(0.03"),DN100-150(4~6")为1.1mm(0.045") , |

| DN200(8"及以上)为1.5mm(0.06")。 |

|

4,管端的外表面不得有焊缝或杂物,并与管道外表面齐平。管端的内表面应清洁,无油污,并清除氧化皮等,以免损坏滚槽压轮。 |

|

5,尺寸A:为密封面长度,是密封圈的密封工作区域,这个区域不得有凹陷,突起和压轮的压痕等,以确保密 |

| 封圈无泄漏,安装前必须清除所有的油,脂及污垢等。 |

|

6,尺寸B:为沟槽宽度,与密封面长度,接头键的宽度相配合,实现柔性接头的挠性。注意沟槽底部的圆角。 |

|

7,尺寸C:为沟槽底部直径,非常关键,必须与管道外径同心,沟槽深度在整个圆周上应均匀一致。 |

|

8,尺寸D:标准沟槽深度,仅是参考值,管端外径的变化将影响该尺寸,沟槽深度需适时调整,确保尺寸C处 |

| 于公差范围之内。注意:沟槽必须满足C尺寸的要求。 |

|

9,允许最小壁厚T: |

|

| |

|

|

| |

|

|